An increasing number of poultry farms use heat exchangers to make sure that the fresh, cold outside air is warmed up before it is delivered to the poultry house. The air is warmed up by exchanging heat between the air that is extracted from the house and the fresh outdoor air that is introduced into the house. The proper use of heat exchangers results in considerable savings on heating costs. However, the major advantage they bring is that the climate in the house improves, thus improving animal performance.

How your heat exchanger works

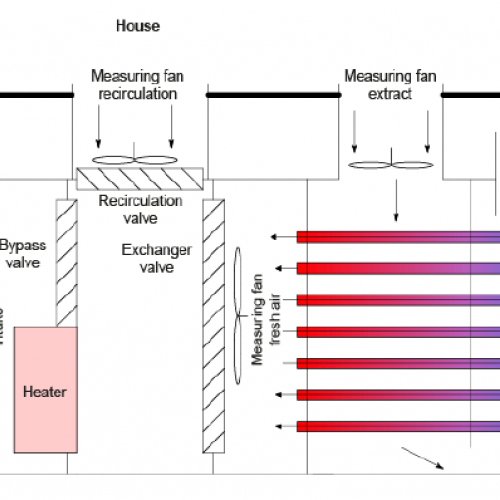

The operating principle of the heat exchanger is as follows:

- The warm air from the house flows through the airflow transmitter and into the heat exchanger and spreads throughout the heat exchanger.

- The relatively cold outside air flows into the heat exchanger and is guided through the louvres and into the house.

- A heat transfer (counterflow) process in the heat exchanger causes the cold outside air to be heated by the warm air from the house.

- The heated outside air flows into the house through the air inlet.

- Circulation fans distribute the fresh air through the house.

In order to make optimum use of the heat exchanger, it is vital that all the elements are adjusted and set correctly.

Aspects to consider as regards controlling your heat exchanger

- The heat exchanger takes care of the first step in the minimum ventilation process. You should carefully adjust the heat exchanger control (equal pressure) to the main ventilation system control (underpressure) and ensure gradual transitions that do not stress the animals. This works best if the heat exchanger control has been integrated with the ventilation computer.

- Make sure that the fresh air is distributed properly throughout the house and avoid any areas where there is no fresh air circulation. A louvre control directs the air to the ridge of the house so that it is mixed properly with the air that is already in the house and prevents cold air from dropping onto the animals. The circulation fan speeds should adjust to changing conditions without the air speed becoming too high.

- Ask for proper advice as regards the circulation fan positions in combination with the air inlet valves and the position of the heating in the house, so as to not disturb any air flows.

- If the air inlet through the heat exchanger is deactivated, the ventilation system should automatically switch over to the main ventilation system, but the heat exchanger's exhaust should continue to operate so that any extra fine particles are filtered out. According to the guidelines, this should constantly run at 1.0 m3/h per animal.

- Check that the airflow transmitter in the heat exchanger features an extra alarm control. This will alert you to any problems in the scrubber and it is a safeguard that sufficient fresh air is introduced into the house at all times.

- Make sure that extra heating control has been added to control the heating in the heat exchanger. This improves the effect of the heat exchanger and reduces heating costs.

- An extra rinse control enables phased rinse timer control in order to ensure that the water pressure is always sufficient.

- Check that all the data that you have to provide to any local authorities is recorded automatically.

Lumina 38H heat exchange control

The Lumina 38H climate computer with heat exchange control provides extensive control possibilities to ensure the most efficient heat exchanger operation and combines this with a perfectly controlled climate. The touch screens give clear and transparent live process overviews, adding to the system's ease of use. The FarmManager software on the PC automatically saves the heat exchanger records required; a smartphone app gives poultry farmers a 24/7 connection with their houses, from any location. This saves time and prevents errors, and thus greatly improves the daily management of a modern poultry farm.