Augmented reality increases the capabilities of our assembly team

Fancom is currently conducting research in collaboration with TNO Leiden and Metaalunie on the potential application of augmented reality (AR) in our assembly department. The application of AR is an initiative of Wim Berden, Assembly Manager at Fancom. Through Metaalunie, Wim learned about this new technique and was immediately enthusiastic: “Harnessing the potential of AR should lead to simplification of the work and higher continuity, quality and effectiveness. In this way, employees with lower qualification levels can be deployed, the learning period can be reduced, and we can increase the efficiency and accessibility of our assembly process. All this, of course, without compromising the quality of our products."

Augmented reality makes employees more independent

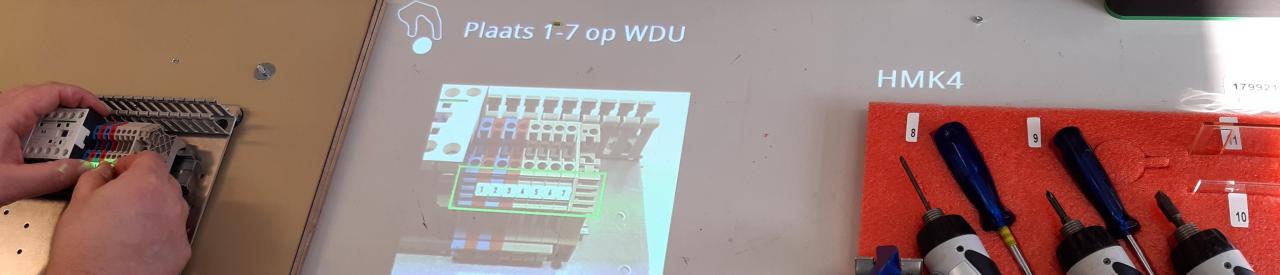

Augmented reality (AR) also makes it possible to project instructions at the place of work, so that employees without previous training can carry out tasks that would be otherwise impossible for them. A projector projects step-by-step work instructions on a work surface or on the product. Employees are able to see what they should do at that particular time, which means that people without any experience can start work straight away. This innovative technology increases our employees' ability to work more independently and tackle more complex work.

Enjoy the work more

Collaboration between people and machines is very much a live issue at the moment in the high-tech manufacturing sector. The technical possibilities are growing and it is becoming increasingly difficult to source well-qualified technical personnel. The application of AR is a perfect match with Fancom's assembly process where we deal with many different high-tech product variants and mass production is a rare occurrence. It means that our team can be deployed more extensively, more broadly, and at a higher skill level. And it also benefits our employees because a wider employability and working accurately boosts their self-confidence and helps them enjoy their work more.

Benefits already visible

The trial currently running in our assembly department is a good example that demonstrates the possibilities of AR. Apart from the fine technology, we have already identified a number of points in the preparations, that we can apply to improve the process. After the trial, we will evaluate the results together with TNO, Metaalunie and the four other participating companies to see whether AR will be assigned a definite role at our assembly department.

Forward

thinking